What is CCX?

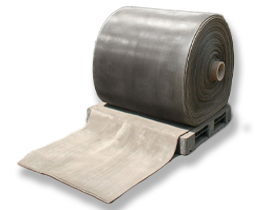

CCX® is primarily used for lining uniformly profiled erosion control applications. CCX® consists of two interconnected layers of geotextile that encapsulate a specially formulated dry concrete mix. CCX-MAT® (CCX-M®) is a variant of CCX® with an LLDPE geomembrane backing which ensures the material has very low permeability.

CCX-M® can be rapidly unrolled to line and remediate canal infrastructure. It is significantly faster, easier and more cost-effective to install than conventional lining methods. CCX® can be hydrated either by spraying or by being fully immersed in water.

As a result, CCX-M® is the ideal solution for the lining and remediation of large channels such as irrigation canals, increasing their operational life and reducing water seepage losses.

CCX-UTILITY® (CCX-U®) is a variant of CCX® without an LLDPE backing. Whilst unsuitable for hydraulic applications such as channels, it may be used to line uniformly profiled slopes.

User Benefit

Rapid Installation

The speed of installation and high early strength gain means that infrastructure downtime is minimised. In critical infrastructure, where maintenance shut-down periods are fixed, this allows for much greater areas to be lined or repaired.

Reduced Seepage

CCX-M® prevents widespread cracking in concrete liners caused by ground movement, reducing seepage, undermining, and potential collapse. Its embedded fiber reinforcement allows for significant ground movement while maintaining low permeability.

Composite Solution

CCX-M® combines the low permeability of a geomembrane with the protection and durability of concrete. It can be installed as rapidly as conventional geosynthetics and 24 hours from hydration will cure to create a hard-wearing concrete liner which is ready to use.

Low Logistical Footprint

CCX® has an un-hydrated unit weight of 14.5-15.5kg/m² compared to ~220kg/m² for 10cm of cured concrete. This means it is typically more than 10x more efficient in terms of the logistical footprint, requiring fewer trucks and reducing operational overheads.

CCX Applications

CCX Properties

- Low Permeability

CCX-M® has an LLDPE geomembrane backing ensuring the material has very high impermeability, significantly reducing or eliminating seepage losses.

- Durable

CCX® has a high degree of durability with abrasion resistance more than 3.5 times that of standard OPC concrete.

- Long-Term Performance

CCX® has very good long-term performance with a life expectancy in excess of 50 years.

- Lower Carbon

CCX® is a carbon efficient concrete solution that offers significant embodied carbon reduction compared to conventional concrete linings.